The power of a production scheduling model is a function of the intelligence that is built into its it's design and it's algorithms. Here is a sample. We want you to understand what is going on under the hood. This should not be a black box.

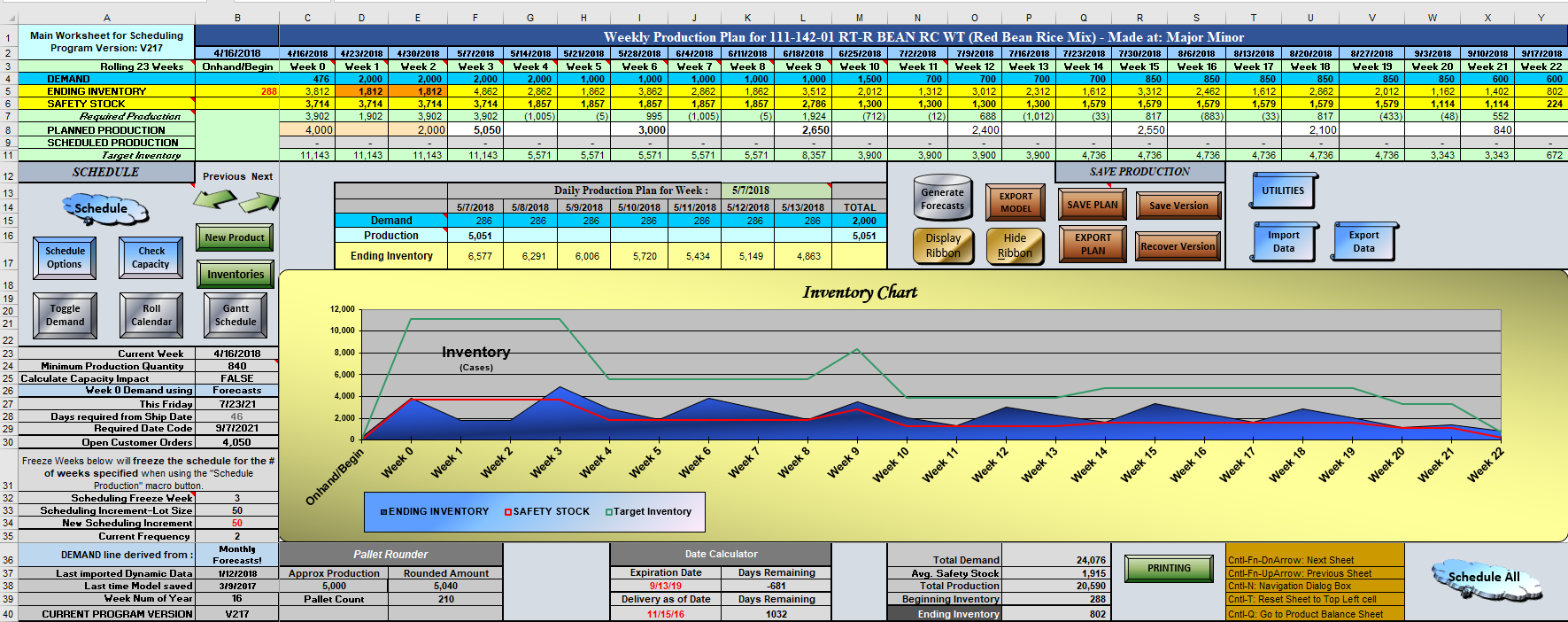

There are three parts to every trip: starting point, path/route, and destination. The starting point for a production schedule is the current on-hand inventory. When the starting inventory is inaccurate then all the scheduling based on it is wrong and costly. Typical symptoms are expedited shipping, stock-outs and schedule interruptions. Building a scheduling model forces you to examine the timeliness of the data especially from third party warehouses. Every time you want to update the current inventory, ensure that all transactions have been posted to the systems (internally and externally). Note that current (perpetual) inventory is a calculated number based on all transactions at each location. These are only adjusted when a physical count is made at the respective location. Also note that in-transit inventories are also counted, up to the time ownership transfers.

The model can be setup to visualize the entire supply chain network or a more limited scope. This distinction is not an option in an ERP system. A distribution routing table determines the supply location for each distribution point in an ERP system. Demand on a manufacturing facility is the result of replenishment signals from sales locations and storage locations (warehouses or terminals). All it takes is one location to indicate that a replenishment is needed to indicate a production demand. There may be an abundance of inventory is the supply chain network. The recommended model setup is to use it as a network model, thereby aggregating all demand and inventories. The model's safety stock calculation would thereby be understood to represent the entire network. This prevents false signals on manufacturing. Think about it. You do not want to make more product than is really needed? Manufacturing is your most valuable asset. Management of asset utilization is the foundation of profitability and customer service.

Another initial data point for production scheduling is demand, which is a combination of customer orders and forecasts. Sounds simple but how these two data sources are combined and what they represent are important. Customer orders are slotted, meaning they have a precise expected ship data. In the short term (current week), they may represent all or a significant part of the demand. More so, they act as a tracking signal to how well forecasts predicted the amount of total demand. If customer order are significantly different than the forecasts then you may want to go back and question future demand. The sooner you can react to a changing environment the better. You may even want to question certain placed orders, if you are in an allocation environment. Should an "A" customer be penalized if they provided a forecast and a "C" customer placing a last minute order and didn't provide a forecast?

Forecasts are typically provided on a monthly basis. The software algorithms will evenly amortize the monthly numbers into weekly buckets. This is a slotting process. In the short term this may be important. It looses significance in the longer term. However, there may be patterns that routinely occur during the months. Some times, more demand may be experienced at a particular time of the month. The software allows you to individually adjust the weekly slotted forecast.

Finally, when the customer orders are combined with the slotted weekly forecasts there are different algorithms in the successive weeks. The user has the option to use either exclusively use customer orders in the current week or use a combination of customer orders and forecasts. The next successive few weeks use - greater than logic. If customer orders exceed the forecasts then the aggregate product level customer orders will be used to drive the requirement on manufacturing. There is also the possibility that not all customer orders have been placed yet. In that case, forecasts may be higher than the running aggregate demand created by customer orders. Even further out in time, most customer orders have not been placed yet and have no significance on manufacturing requirements. These weeks are exclusively forecast driven.